I've been wanting to learn to use HHG for a while now and have played with it a little, sometimes it seems ok and sometimes not. There was a discussion a few days back on fish glue and naturally HHG came up in that as they are realted. I believe Paul Woolson might of mentioned he had similar experiences to mine, Paul correct me if I'm wrong.

Any way to make a long story longer, I mananged to hook up with a well established Cello maker somewhat near me and she went over her HHG proceedure. She measures nothing and really encouraged me to try HHG again, so using her approach I tried again.

So.. here's what I did.

I used an Maccasser Ebony bridge blank (from the Zoot man himself) and a scrap from an old top, looked like sitka.

Prepped the ebonywith a scraper and the sitka was sanded to 220.

I did monitor the temp of my rival hot pot but did not measure the amount of water I used. I just added water until it was just a little over the top of the glue.

My shop was not quite as warm as the photo indicates there was a portable light shining on the thermometer. It was actually about 77 F. and as you can see the HHG was about 140ish.

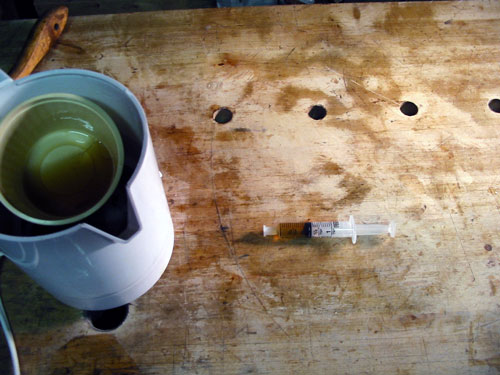

The mixed glue looked like this and I used an oral syringe to dispense the glue with.

Next I thinned out some HHG with water and wiped it on both surfaces, the way my cello maker friend does it.

These sat around for approximately 10 minutes before actually being glued up while I was getting my vacuum set up ready.

IMG]useruploads/JimW/2006-08-19_133908_hgt3.jpg[/IMG]

I then took my HHG syringe from the hot pot and applied a generous amount of glue to the bridge blank. I made no special effort to work extra fast nor did I heat the bridge blank. Then I placed the assembly in my vaccum frame, I use vacuum to clamp my bridges on so it was representative to me.

I left the assembly under pressure for 30 minutes and removed it form the vacuum press and set it aside.

I then ripped it apart 12 hours later and this is what I got.

I'll repeat this test a few times to make sure I actually have a process.

Hopefully out of this long winded thing it'll encourage others who are interested it HHG but aren't so sure. It's encouraged me to keep exploring it.

[/QUOTE]

[/QUOTE]